ABS Sheet

Best material of automobile components

Excellent impact resistance, ease of processing, and dimensional stability.

An excellent material for vacuum forming.

Common applications:

✅ Automotive and motorcycle parts and shells

✅ Printed materials

✅ 3C accessory packaging

✅ Household appliances (refrigerators, shells, vacuum cleaners, etc.)

✅ Toy materials

✅ Advertising signs, medical equipment supplies

✅ Luggage and suitcase shells, etc.

Ta Fu Chi Plastic ABS Sheet Types

• ABS Sheet with PVC Wood Grain Film

✅ Aesthetic, suitable for furniture or decorative products

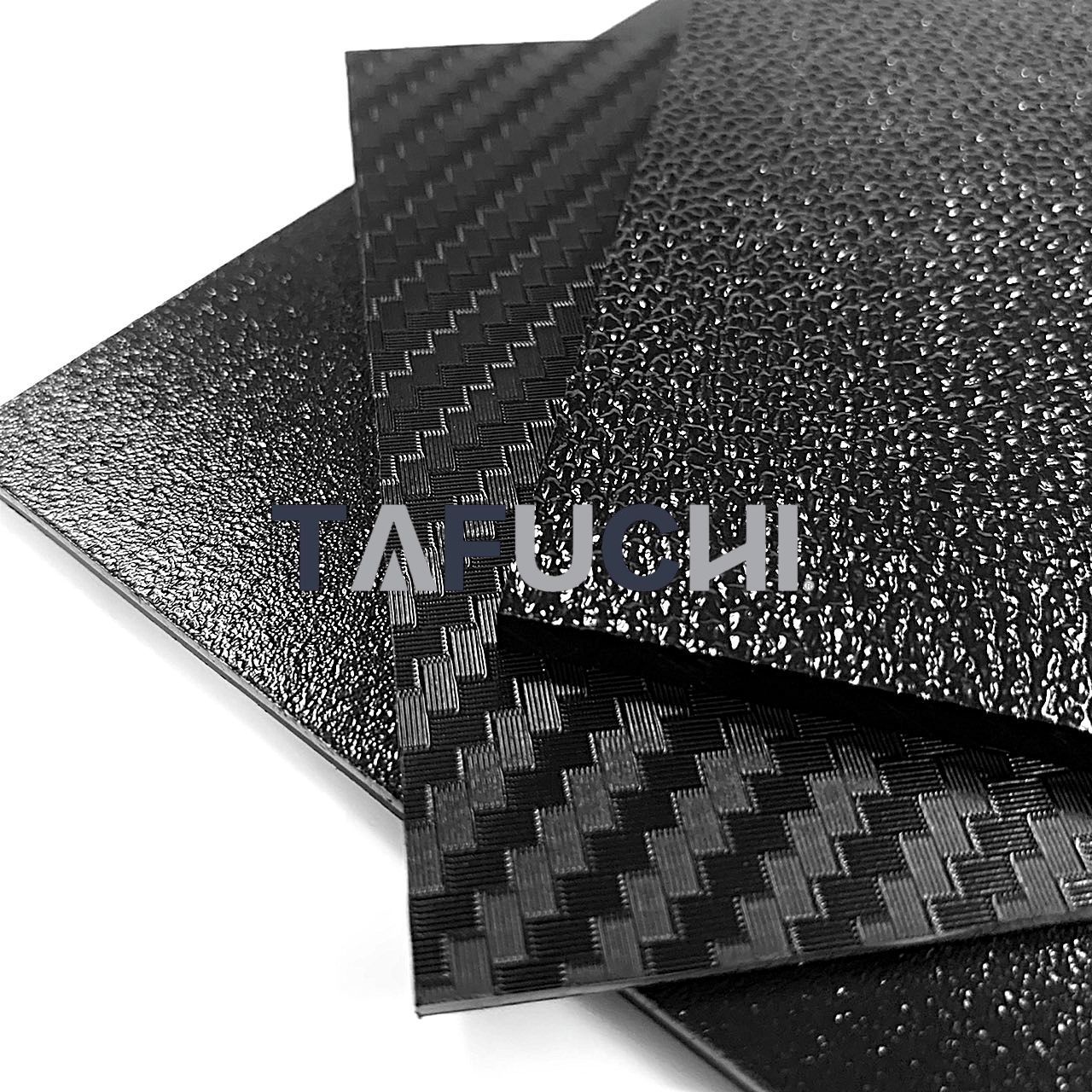

• ABS Thick Sheet (ABS Textured Plastic Sheet)

✅ Textured surface, resistant to scratches

• ABS Thin Sheet (ABS Plastic Plate)

✅ Thinner thickness, suitable for printing applications

Product Features and Customization Services

• Various sizes and thicknesses can be customized based on requirements

• Customers can select the appropriate product based on processing methods and intended use

• Suitable for various OEM and ODM cooperation development needs

Ta Fu Chi Plastic Cooperation Philosophy

• Focused on quality and innovation

• Eager to collaborate with customers on new product development

• Aiming to establish long-term partnerships for mutual success

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

ABS Sheet | Durable, High-Quality Plastic Sheet Solutions for Every Application

Ta Fu Chi Plastic Co., Ltd. is a leading ABS Sheet manufacturer in Taiwan with over 30 years of expertise in plastic extrusion. We specialize in producing high-performance materials such as acrylic sheet, matte acrylic sheet, acrylic edge banding, and pvc wood-grain sheet, all designed to meet the evolving demands of the furniture and interior design industries. By combining advanced manufacturing processes with flexible customization options, we offer solutions that are not only visually striking but also durable, cost-effective, and easy to process. Our commitment to quality and precision has made us a trusted partner for global B2B clients across kitchen, wardrobe, and bathroom furniture manufacturing.

Headquartered in Tainan, Taiwan, Ta Fu Chi Plastic serves customers worldwide with a focus on innovation, reliability, and environmental responsibility. We continually develop materials that meet both aesthetic and functional needs—offering moisture-resistant edge banding, scratch-resistant surfaces, and rich color options. Our plastic sheets are ideal alternatives to traditional materials like glass, metal, or wood, helping manufacturers achieve modern designs with improved production efficiency. With a foundation built on customer satisfaction and long-term success, we are proud to deliver plastic sheet solutions that enhance the value and performance of today’s furniture applications.