High Impact Polystyrene Plastic Sheet

Rigid Hips Plastic Sheet

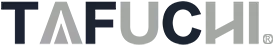

HIPS Sheet

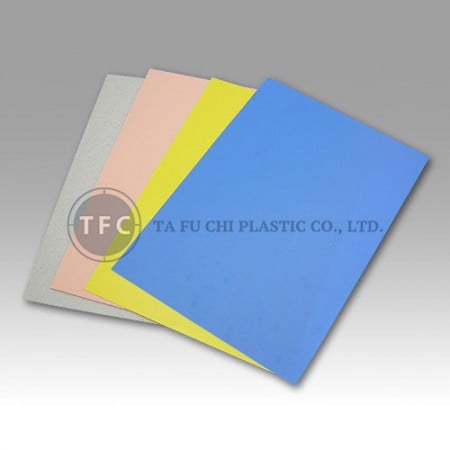

The impact-resistant polystyrene is made by adding polybutadiene rubber to HIPS which is non-toxic and environmentally friendly. It is often used in the food and packaging industries. Compared to GPPS, HIPS has a high rubber content and a high impact resistance. When subjected to impact, the stress of crack expansion is released by the soft rubber to improve impact resistance. Another advantage is heat resistance. HIPS can be used for vacuum forming, printing, cutting, injection, extrusion, and other processing, and can be used in a variety of product shapes. Good processing characteristics and competitive prices make the material popular.

The main application of HIPS are packaging materials, housings of household appliances, toys, and so on.

1. Various shells: HIPS is widely used in the shells of TVs, telephones, air conditioners, washing machines, printers, lighting fixtures, refrigerators (lining, shell), and office supplies.

2. Packaging materials: HIPS is widely used as food packaging materials (cup, food box, fruit plate, gift box inner plate), electronic packaging material (antistatic plastic sheet can be selected)

3. Other products: medical equipment, drainage boards, partitions for decoration and toys (printable)

Features

- None toxic.

- High heat resistance.

- High impact strength.

- Good machinability.

- Outstanding thermoforming characteristics.

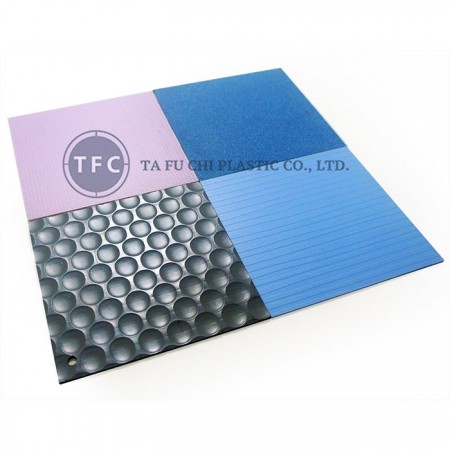

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 0.25mm ~ 7mm | 600mm | 600mm | White | Corona Treatment UV Resistant Forming Grade Print Grade |

| 1000mm | 1250mm | Black | ||

| 1500mm | 1830mm | Custom Size | ||

| Custom Size |

APPLICATION

- The beverage cup uses HIPS board, which is beautiful and environmentally friendly.

- Playing card can be made by polystyrene sheets.

- Cutlery trays

- seed trays

- The shell of household appliances uses HIPS to reduce production cost and gradually replace the shell formed by ABS board.

- The food lunch box uses HIPS, which is environmentally friendly and heat-resistant, and convenient to use.

- Related Products

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

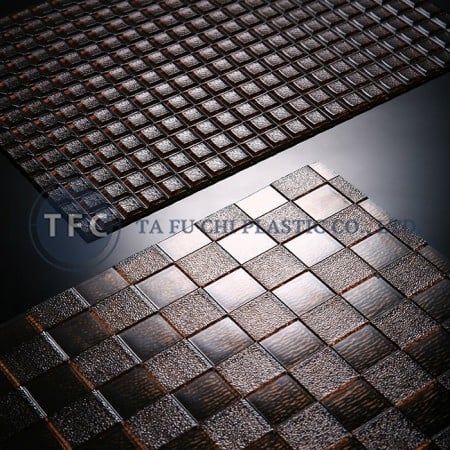

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

High Impact Polystyrene Plastic Sheet | Taiwan-Based Plastic Sheet Supplier for Global Markets

Ta Fu Chi Plastic Co., Ltd. is a leading High Impact Polystyrene Plastic Sheet manufacturer in Taiwan, specializing in the production of high-quality acrylic sheet, abs sheet, hips sheet, pmma sheet, and pvc wood-grain sheet. With over 30 years of experience in the plastic extrusion industry, we are committed to providing consistent quality, customizable specifications, and advanced sheet solutions for a wide range of industrial, commercial, and furniture applications. Our in-house extrusion technology and production control enable us to deliver plastic sheets in various finishes, colors, and thicknesses that meet international standards.

As a trusted plastic extruder and OEM supplier, Ta Fu Chi Plastic has successfully manufactured and exported over 100,000 metric tons of plastic sheets worldwide. Our diverse product range includes ps embossed sheet, acrylic capped abs sheet, and other specialty sheets designed for durability, impact resistance, and aesthetic appeal. Whether used in kitchen cabinets, bathroom fixtures, automotive interiors, or signage, our products combine function and form to meet the needs of global buyers. We continue to grow as a reliable partner in delivering tailored plastic sheet solutions that enhance manufacturing efficiency and end-user satisfaction.