ABS Sheet

Best material of automobile components

Ta Fu Chi Plastic has more than 30 years of experience in extruding plastic sheets and a specialized know-how on ABS plastic sheets. An ABS plastic sheet is particularly well-suited for vacuum forming. It is widely used in automobile and motorcycle parts and shells, printing, furniture, 3C accessories, daily necessities, household appliances (in the refrigerator, shell, vacuum cleaner), toy products, building decoration materials, advertising signs, medical equipment supplies, luggage and suitcases and so on.

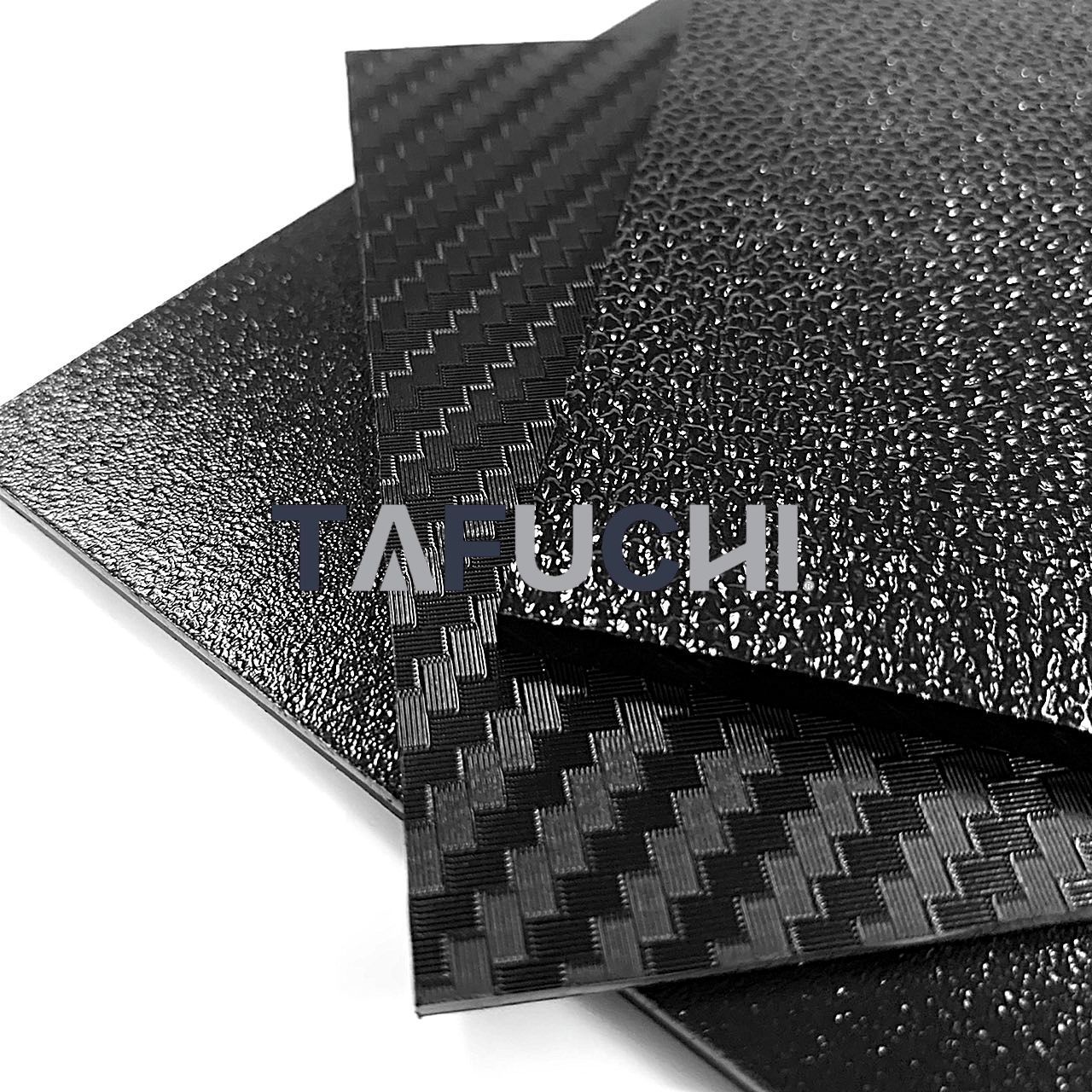

Ta Fu Chi Plastic has three kinds of ABS plastic sheets with customed sizes. There are ABS sheet cover with PVC wood grain film, ABS textured plastic sheet, and ABS plastic plate. The difference between an ABS textured plastic sheet and an ABS plastic plate is the thickness. Depend on the customers' needs and processing methods customers used to choose a suitable ABS sheet. Ta Fu Chi Plastic loves to work with you on new products and looks forward to having a long-term relationship with the ODM and OEM.

FEATURES

- The ABS sheet has high impact resistance and is suitable for application in various areas of daily life.

- The ABS sheet has a high gloss effect surface and a matt effect surface of the customer's choice.

- Easy to shape and process, including computer color matching, weathering resistance, precision cutting, CNC machining, panel lamination, vacuum forming, printing, back-coating, and stamping.

- The ABS sheet has good chemical stability and can be combined with PMMA, PVC and PC to enhance physical properties and provide more functionality.

SUGGESTION

- Our other product, an ASA sheet, is more suitable for outside usage than an ABS sheet because it can withstand ultraviolet.

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

ABS Sheet | Durable, High-Quality Plastic Sheet Solutions for Every Application

Ta Fu Chi Plastic Co., Ltd. is a leading ABS Sheet manufacturer in Taiwan with over 30 years of expertise in plastic extrusion. We specialize in producing high-performance materials such as acrylic sheet, matte acrylic sheet, acrylic edge banding, and pvc wood-grain sheet, all designed to meet the evolving demands of the furniture and interior design industries. By combining advanced manufacturing processes with flexible customization options, we offer solutions that are not only visually striking but also durable, cost-effective, and easy to process. Our commitment to quality and precision has made us a trusted partner for global B2B clients across kitchen, wardrobe, and bathroom furniture manufacturing.

Headquartered in Tainan, Taiwan, Ta Fu Chi Plastic serves customers worldwide with a focus on innovation, reliability, and environmental responsibility. We continually develop materials that meet both aesthetic and functional needs—offering moisture-resistant edge banding, scratch-resistant surfaces, and rich color options. Our plastic sheets are ideal alternatives to traditional materials like glass, metal, or wood, helping manufacturers achieve modern designs with improved production efficiency. With a foundation built on customer satisfaction and long-term success, we are proud to deliver plastic sheet solutions that enhance the value and performance of today’s furniture applications.