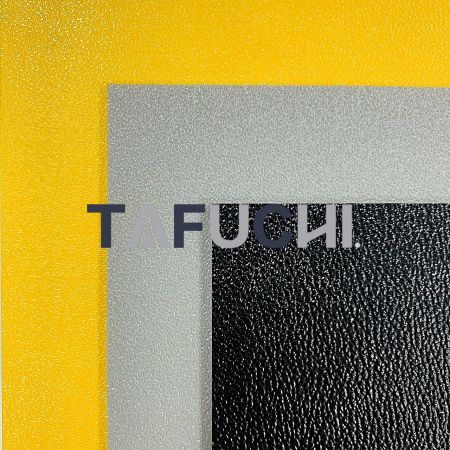

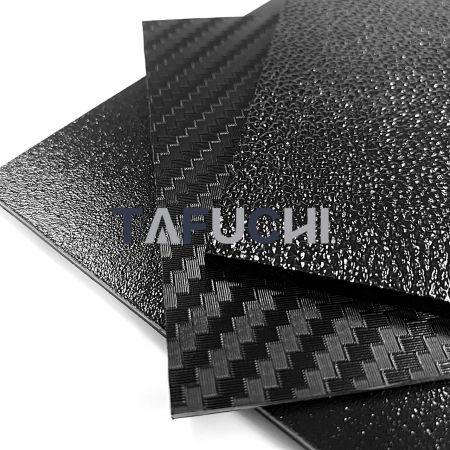

ABS Sheet

Vacuum Forming ABS Sheet

ABS Plastic Sheet; ABS Textured Sheet; ABS Haircell Sheet

ABS sheet is a high molecular plastic sheet composed of copolymers of acrylonitrile, butadiene, and styrene. Its diverse characteristics and wide range of applications make it a favored choice among customers, establishing itself as one of the commonly used plastic sheets in various industries.

Characteristics

1. Impact Resistance: ABS sheets are renowned for their excellent impact resistance, making them suitable for environments that require resistance against external forces.

2. Easy Processing and Shaping: ABS sheets are easy to process into various shapes, making them an ideal material for manufacturing a variety of products. They can be crafted into different shapes through processes such as thermoforming, vacuum forming, and other methods.

3. UV Resistance: Some ABS sheets are enhanced with UV-resistant agents, making them more suitable for outdoor applications, such as automotive shells and other products that require protection against UV radiation.

4. Cold Resistance: Specially treated ABS sheets maintain their performance in low-temperature environments, making them suitable for applications in cold conditions, such as sleds, refrigerator interiors, and medical equipment.

5. Antistatic Properties: Specially treated ABS sheets exhibit antistatic properties, making them suitable for packaging electronic products.

Applications

1. Automotive Industry: ABS sheets find extensive applications in automotive components, interior decorative panels, and vehicle exteriors, leveraging their impact resistance and processing capabilities.

2. Electronics: Antistatic ABS sheets are commonly used in packaging electronic devices to ensure that static electricity does not damage sensitive electronic components.

3. Outdoor Products: ABS sheets with UV resistance are suitable for outdoor products, including outdoor signs, billboards, and other items exposed to sunlight for extended periods.

Ta Fu Chi Plastic provides customized ABS sheets with a variety of sizes, colors, specifications, and surface patterns (embossing, bonding). These sheets are resistant to scratches and exhibit high wear resistance. In terms of processing, ABS sheets can be treated through various methods, expanding their application range, including weathering treatment, CNC machining, sheet lamination, vacuum forming, printing, back coating, stamping, coating, plating treatment, spraying metal, welding, and bonding, among others. Additionally, the company offers other ABS composite materials, such as ABS/ASA sheets, ASA sheets, and ABS/PMMA sheets. Feel free to inquire at any time.

Features

- Good machinability.

- Excellent impact resistance.

- Good strength and stiffness.

- Good chemical resistance.

- High heat resistance.

- Excellent water resistance.

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 0.25mm ~ 7.0mm | 1000mm | 500mm | White | Transparency ABS UV Resistant Various patterns |

| 2000mm | 1830mm | Black | ||

| 2800mm | Custom Size | Custom Color |

- Related Products

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

ABS Sheet | Taiwan-Based Plastic Sheet Supplier for Global Markets

Ta Fu Chi Plastic Co., Ltd. is a leading ABS Sheet manufacturer in Taiwan, specializing in the production of high-quality acrylic sheet, abs sheet, hips sheet, pmma sheet, and pvc wood-grain sheet. With over 30 years of experience in the plastic extrusion industry, we are committed to providing consistent quality, customizable specifications, and advanced sheet solutions for a wide range of industrial, commercial, and furniture applications. Our in-house extrusion technology and production control enable us to deliver plastic sheets in various finishes, colors, and thicknesses that meet international standards.

As a trusted plastic extruder and OEM supplier, Ta Fu Chi Plastic has successfully manufactured and exported over 100,000 metric tons of plastic sheets worldwide. Our diverse product range includes ps embossed sheet, acrylic capped abs sheet, and other specialty sheets designed for durability, impact resistance, and aesthetic appeal. Whether used in kitchen cabinets, bathroom fixtures, automotive interiors, or signage, our products combine function and form to meet the needs of global buyers. We continue to grow as a reliable partner in delivering tailored plastic sheet solutions that enhance manufacturing efficiency and end-user satisfaction.