Plastic Sheets For Furniture Application

High-gloss Acrylic Sheet/ Matte Acrylic Sheet/ Acrylic Edge Banding/ PVC Wood-grain Sheet

In the furniture industry, in contrast to common materials such as metal, stone, glass, aluminum alloy, and wood, plastic materials have the characteristics of easy processing, durability and reliability, rich colors and low cost. Additionally, adding different additives to plastic can achieve different functionalities. Also, different types of plastic materials and different processing methods can reach different designs and matching styles.

The high-gloss acrylic sheet of Ta Fu Chi Plastic, with customized colors and mirror effects, expands the visual sense of space and gives a noble, simple style. They are often used as kitchenware panels, wardrobe panels, bathroom cabinet panels, etc. The acrylic edge bandingof Ta Fu Chi Plastic can effectively prevents moisture and has no gap at the joints, which is an effect that other plastic materials cannot achieve. The matte acrylic sheet of Ta Fu Chi Plastic has customized colors, wear-resistant properties and is easy to care for. The matte effect is different from the high gloss, creating an elegant and comfortable sense of space. Going with the acrylic edge banding of Ta Fu Chi Plastic, the overall looking is more consistent. They are often used on kitchen panels, decorative panels, etc. Ta Fu Chi Plastic provides PVC laminated ABS sheetwith different wood grains. The surface is scratch-resistant. Warm colored wood grains can greatly improve sense of vision.

- Related Product

ABS Sheet Cover With PVC Wood Grain Film

PVC wood veneer sheet

ABS laminated PVC wood grain sheet is a composite panel composed of an ABS base layer laminated with a PVC wood grain surface layer. This structure combines the impact resistance, dyeability, high hardness, low water absorption, corrosion resistance, non-toxicity, odorlessness, excellent chemical properties, and electrical insulation of ABS sheet with the simulated wood grain texture of PVC wood grain.The characteristics and advantages of the sheet include:1. Lightweight: Due to the lightweight of ABS and PVC materials, ABS laminated PVC wood grain sheet is relatively light, making it easy to carry and install.2. Impact resistance: The ABS base layer provides the sheet with excellent impact resistance, making it suitable for various environments.3. Variety of colors and wood grain effects: The PVC wood grain layer offers natural, rich colors and presents simulated wood grain, meeting different design needs.4. Wear resistance and stain resistance: Due to the characteristics of the PVC wood grain layer, this type of sheet has superior wear resistance and stain resistance.5. Aesthetic and fade resistance: PVC wood grain board is aesthetically pleasing and resistant to fading, making it an ideal choice for long-term use.6. Substitute for solid wood materials: Due to its various advantages, ABS laminated PVC wood grain sheet is often used to replace solid wood panels and is widely applied in interior decoration, furniture manufacturing, door and window production, and other construction material fields.ABS sheet can also be laminated with other materials, such as wood grain paper, acrylic film, and other surface decorative materials, further expanding its application range. This application is widespread in automotive, printing, furniture, 3C accessories, daily necessities, household appliances, toy products, building materials, advertising signs, medical equipment, hard-shell luggage, and plastic casing industries, among others. Ta Fu Chi Plastic offers single-sided wood grain sheets and double-sided wood grain sheets, and can customize production according to customer requirements, providing various appearance choices and design flexibility.

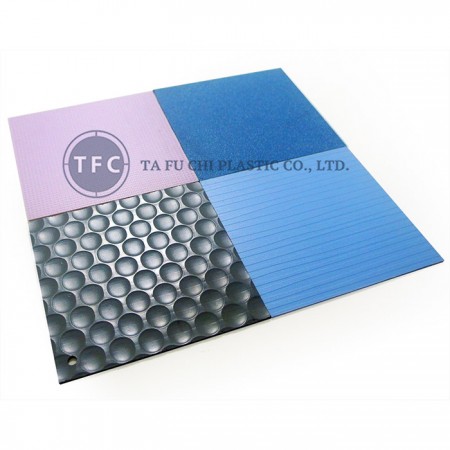

ABS Plastic Plate

ABS Styrene Plastic Plate Sheet

ABS Plastic Plate of Ta Fu Chi plastic has the following main characteristics and applications,Characteristics:1. Outstanding Impact Resistance: ABS thin sheets exhibit excellent impact resistance, making them suitable for applications that require resistance to impact.2. Ease of Processing and Shaping: Due to the plasticity of ABS material, thin sheets can be easily processed and shaped to meet specific customer requirements.3. Wide Range of Widths: Available in widths ranging from 400mm to 850mm, and can be packaged in rolls, facilitating subsequent processing by customers.4. Polar Surface: ABS sheets have a polar surface, making them suitable for products requiring surface painting.5. High-Temperature Resistance and Environmental Friendliness: Compared to PVC, ABS has higher temperature resistance and is more environmentally friendly, leading to widespread use in various applications.6. Versatile Applications: Primarily used in automotive interior decorative panels, furniture industry, 3C accessories, daily necessities, building materials, advertising signs, medical equipment, SIM cards, smart cards, hard-shell luggage, and plastic casings.Applications:1. Automotive Interior Decorative Panels: Used as a substrate for automotive interior decoration, offering impact resistance and high-temperature stability.2. Furniture Industry: Utilized in the manufacturing of furniture components, customizable based on customer needs.3. 3C Accessories: Widely applied in the production of electronic product casings and components.4. Daily Necessities: Used in the manufacture of common household items such as plastic boxes and containers.5. Building Materials: Employed in the production of decorative and structural materials for construction.6. Advertising Signs: Suitable for the manufacturing of indoor and outdoor advertising signs.7. Medical Equipment: Applied in the medical field for various instrument and equipment components.8. Hard-Shell Luggage and Plastic Casings: Due to its high strength and impact resistance, ABS is suitable for manufacturing luggage and casings.In terms of processing, Ta Fu Chi Plastic offers diverse sizes, specifications, and colors, along with various processing methods such as weather resistance treatment, CNC machining, sheet lamination, vacuum forming, printing, back coating, stamping, coating, plating treatment, metal spraying, welding, and bonding, meeting the diverse application needs of customers.

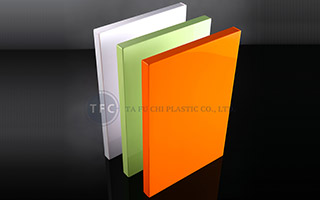

High Gloss Acrylic Sheet

TFC DÉLIC SHEET- HG/ HGC

"DÉLIC" is an acronym for ''décor acrylic". Our product line, TFC DÉLIC SHEET, is specially designed for decorating the panel. TFC DÉLIC SHEET-HG stands for high gloss acrylic sheet; TFC DÉLIC SHEET-HGC stands for high gloss acrylic sheet with scratch resistance. The high gloss acrylic sheet with a reflective high gloss finish is ideal for all furniture fittings in the kitchen, bathroom, living room, bedroom and office. With a mirror-like surface, splendid colors and custom specifications, the High Gloss Acrylic Sheet made from Ta Fu Chi plastic can satisfy your requests for quality and beauty.Further processing can be laminated and thermoformed without affecting its outstanding color and shine. Ta Fu Chi plastic ensures the color of high gloss acrylic sheets by using color measurement systems and spectrometer systems. Besides, Ta Fu Chi plastic provides color matching edge-banding which creates a seamless monolithic look. For further information about edge-banding please refer to our edge-banding page. Ta Fu Chi plastic also provides materials for the reverse surface.Ta Fu Chi plastic continues developing new colors to meet the current trends and customer’s preferences. If you have any further queries, please do not hesitate to send your inquiries by email or by phone.

Acrylic Edge Banding

Acrylic edge banding prevents moisture in serving as a seal on the edge of the panel. The edge banding from Ta Fu Chi Plastic can cover up rough edges and provides a seamless joint to the tops and sides of the panel. Ta Fu Chi Plastic has high-gloss series and super matte series for selection.Ta Fu Chi Plastic provides more than 21 colors that are market-proven colors, and all of them have corresponding colors to our acrylic sheets. We continue to develop new colors of different cultures and customer’s preference.

High Impact Polystyrene Plastic Sheet

Rigid Hips Plastic Sheet

The impact-resistant polystyrene is made by adding polybutadiene rubber to HIPS which is non-toxic and environmentally friendly. It is often used in the food and packaging industries. Compared to GPPS, HIPS has a high rubber content and a high impact resistance. When subjected to impact, the stress of crack expansion is released by the soft rubber to improve impact resistance. Another advantage is heat resistance. HIPS can be used for vacuum forming, printing, cutting, injection, extrusion, and other processing, and can be used in a variety of product shapes. Good processing characteristics and competitive prices make the material popular.

English

English