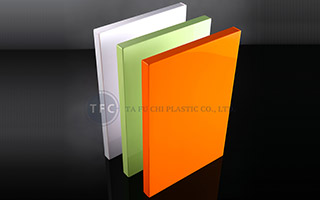

High Impact Polystyrene Plastic Sheet

Rigid Hips Plastic Sheet

The impact-resistant polystyrene is made by adding polybutadiene rubber to HIPS which is non-toxic and environmentally friendly. It is often used in the food and packaging industries. Compared to GPPS, HIPS has a high rubber content and a high impact resistance. When subjected to impact, the stress of crack expansion is released by the soft rubber to improve impact resistance. Another advantage is heat resistance. HIPS can be used for vacuum forming, printing, cutting, injection, extrusion, and other processing, and can be used in a variety of product shapes. Good processing characteristics and competitive prices make the material popular.

HIPS Sheet

The main application of HIPS are packaging materials, housings of household appliances, toys, and so on.

1. Various shells: HIPS is widely used in the shells of TVs, telephones, air conditioners, washing machines, printers, lighting fixtures, refrigerators (lining, shell), and office supplies.

2. Packaging materials: HIPS is widely used as food packaging materials (cup, food box, fruit plate, gift box inner plate), electronic packaging material (antistatic plastic sheet can be selected)

3. Other products: medical equipment, drainage boards, partitions for decoration and toys (printable)

Features

- None toxic.

- High heat resistance.

- High impact strength.

- Good machinability.

- Outstanding thermoforming characteristics.

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 0.25mm ~ 7mm | 600mm | 600mm | White | Corona Treatment UV Resistant Forming Grade Print Grade |

| 1000mm | 1250mm | Black | ||

| 1500mm | 1830mm | Custom Size | ||

| Custom Size |

- Related Products

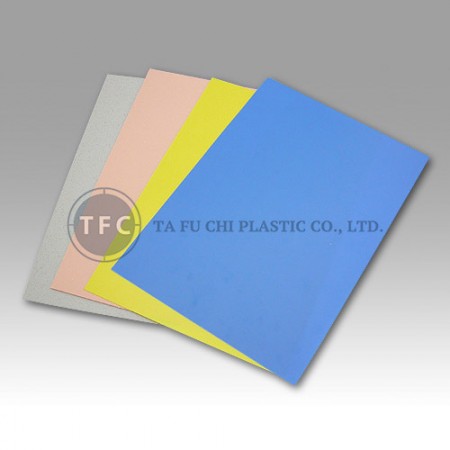

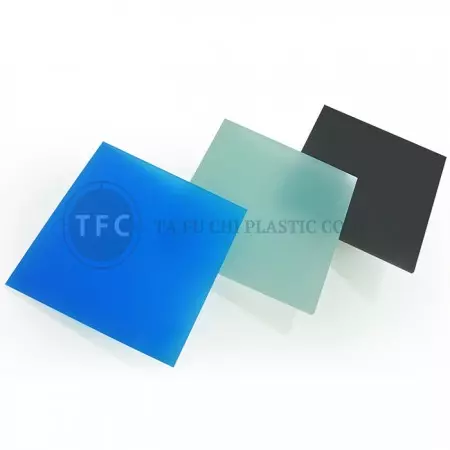

GPPS Frosted Sheet

GPPS frosted sheet is a general-purpose polystyrene sheet with a special matte effect. It is highly valued for its processing features and competitive price, making it popular among customers.Features: 1. Light Transmission: Good light diffusion, allowing light to pass while creating a soft, unfocused effect. 2. Light and Shadow Effects: Its matte characteristic provides unique light-shadow effects, enhancing design appeal. 3. Lightweight: Easier handling due to its light weight compared to other materials. 4. Colorability: Easy to color, suitable for various design needs. 5. Dimensional Stability: Maintains stable dimensions without warping. 6. Electrical Properties: Excellent electrical insulation for applications requiring high electric performance.

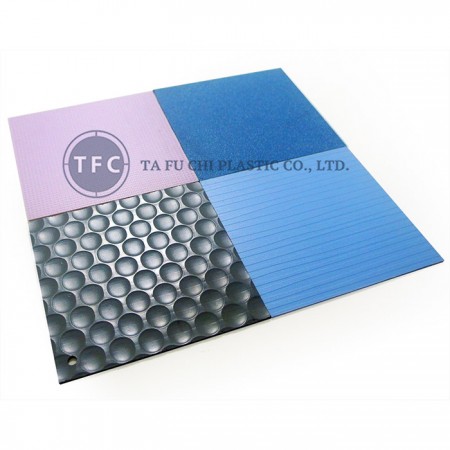

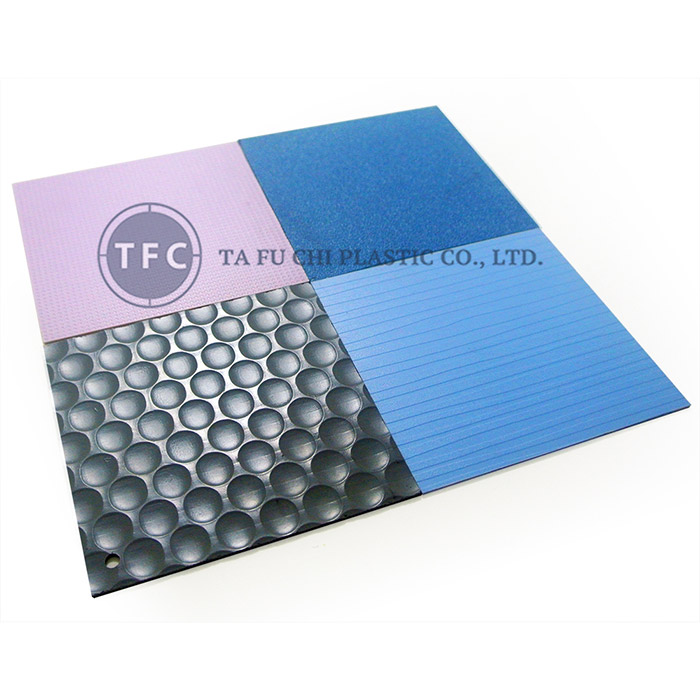

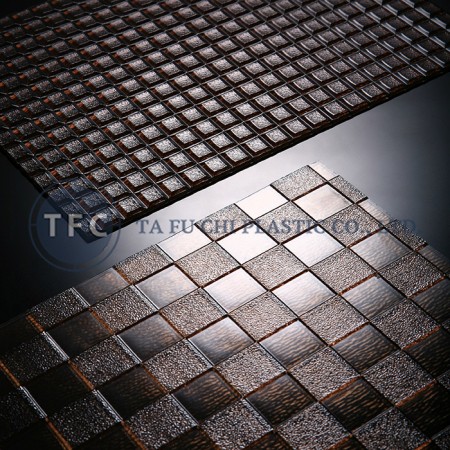

GPPS Patterned Sheet

GPPS Textured Sheet

GPPS patterned sheet is light in weight, low in water absorption, easy to color, good in dimensional stability, good in electrical properties, and easy to process. It can still maintain its mechanical properties and dimensional stability in a humid environment. The surface pattern of the GPPS embossed sheet is similar to stained glass, three-dimensional and layered. The disadvantage is that it is brittle and easy to crack. Compared to HIPS, it has lower impact strength and poor sunlight resistance. GPPS patterned sheet is widely used in shower sliding doors, ceiling lampshades, indoor frosted glass, office compartments, laminates, office equipment, interior decoration materials, daily necessities, toy shells, bathroom equipment, etc. Ta Fu Chi Plastic has more than 22 kinds of patterns, and various patterns have different thinnest thickness limits. Additionally, customized embossing requirements are available. Welcome to contact us for further information.

English

English